Products

Roll Brushes (Disc)

- Roll brushes

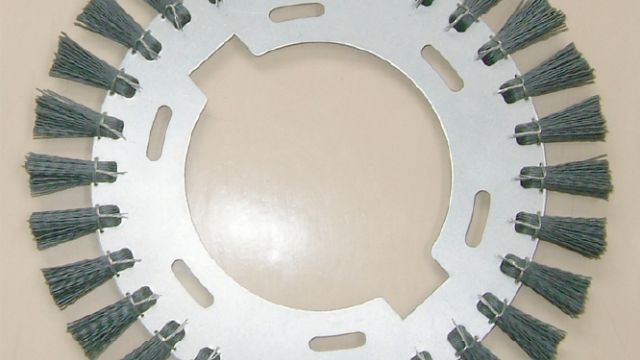

SK Type Disc Roll Brushes

The SK Type Disc Roll Brush is a roll brush made by stacking SK Type Disc Brushes, which have extremely low bristle breakage, is high in density and enables high-performance brushing for a long period of time. It can be used with almost all types of disc roll brush shafts.

Product Variations

Parallel implanting roll brush

Staggered implanting roll brush

SK Type Disc Roll Brush Features

- The SK Type Disc Roll Brush consists of stacked disc brushes, each of which is made by drilling holes in a disc plate and implanting brush bristles into the drilled holes.

- It has extremely low bristle breakage, is high in density and enables high-performance brushing for a long period of time.

- Bristles are implanted independently in each bundle, and thus they stay attached continuously.

- The density of bristles can be controlled by changing the implanting arrangement and assembly, enabling higher density of bristles.

Parallel implanting

This arrangement maximizes the number of bristle bundles on the outer circumference of the disc plate.

Staggered implanting

The bundles of bristles on the outer circumference of the disc and the bundles of bristles on the outer circumference of the adjacent disc are alternately combined.

In the unlikely event of a problem with the disc brush, partial replacement is possible.

Applications and Functions

Washing/cleaning, polishing/grinding, deburring, mill scale removal, etc.

Specifications and Structure

| Disc plate | Galvanized steel sheet, stainless steel sheet |

|---|---|

| Bristle material | Synthetic fiber All types of bristle materials can be used, including bristle material containing abrasive grains and wavy bristle material. |

- Abrasion resistant

- Chemical resistant (resistant to acid/alkali)

- Deburring

- Durable/long life

- Elastic

- Grinding/polishing

- Hard

- Large/long

- Sweeping (cleaning/foreign matter removal)

- Washing

- Wiping (dirt removal)

FEATURES

Features of SHOWA INDUSTRIES

- Development Capability

- Technological Capability

- Proposal Capability